В мире промышленного охлаждения и производства льда льдогенераторы с аммиачной трубкой привлекли значительное внимание благодаря своей энергоэффективности, надежности и экологическим преимуществам. Эта машина, известная производством высококачественного трубчатого льда, идеально подходит для различных применений, включая консервирование пищевых продуктов, хранение морепродуктов, медицинское применение и даже в химической и промышленной отраслях. Аммиачная система, особенно в сочетании с такими передовыми функциями, как двигатели Siemens и маслоотделители, обеспечивает эффективность и долговечность эксплуатации. В этой статье подробно рассматриваются основные компоненты и преимущества льдогенератора с аммиачной трубкой.

Холодильная система на основе аммиака лежит в основе производства трубчатого льда. Аммиак является широко используемым хладагентом благодаря своей эффективности и экологически чистым свойствам. В аммиачных системах хладагент циркулирует по замкнутой системе, поглощая тепло и охлаждая воду в испарителе с образованием льда. Такая конструкция с замкнутым контуром снижает потребление энергии, что делает льдогенераторы с аммиачной трубкой экологически безопасным выбором для крупномасштабного производства льда.

Компания Siemens известна своими передовыми технологиями в области промышленного оборудования, а ее электродвигатели являются ключевым компонентом льдогенераторов с аммиачной трубкой. Двигатель Siemens обеспечивает эффективную передачу мощности, высокую производительность и низкое энергопотребление. Благодаря своей усовершенствованной конструкции он вносит значительный вклад в общую эффективность процесса производства льда.

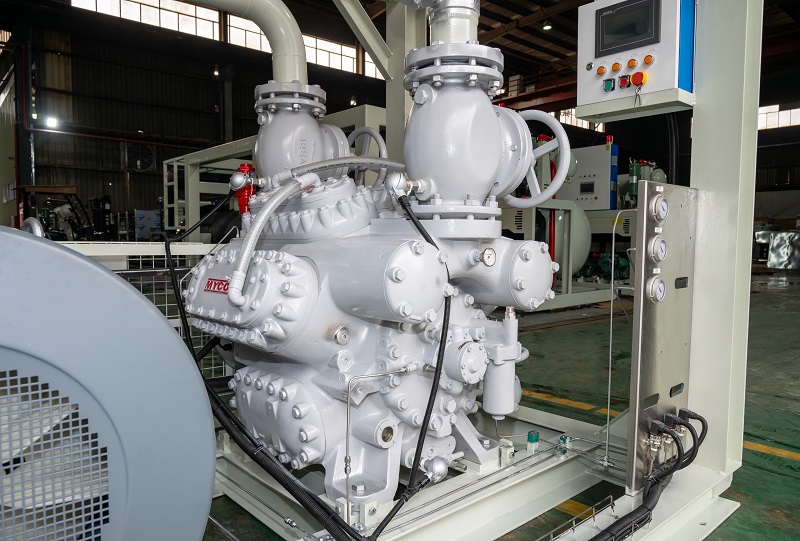

Маслоотделитель играет решающую роль в обеспечении бесперебойной работы системы аммиака. Он отделяет масло от газообразного хладагента, чтобы предотвратить любое загрязнение в холодильном цикле. Поддерживая чистоту и эффективность системы, маслоотделитель продлевает срок службы компрессора и других ключевых компонентов, обеспечивая надежное и стабильное производство льда.

Основная панель управления — это мозг льдогенератора с аммиачной трубкой. Он контролирует и контролирует все аспекты процесса производства льда: от температуры и давления до скорости производства льда. Благодаря передовой автоматизации и данным в режиме реального времени операторы могут легко регулировать настройки для оптимизации производительности и поддержания желаемой производительности льда.

Вспомогательная панель управления обеспечивает вторичное управление конкретными операциями внутри машины. Обычно он управляет вспомогательными функциями, такими как сбор льда, поток воды и процессы размораживания. Этот компонент обеспечивает слаженную работу всех функций, оптимизируя общую эффективность системы.

Компрессор является важной частью любой холодильной системы. Он отвечает за сжатие газообразного хладагента, позволяя начать цикл охлаждения. В льдогенераторе с аммиачной трубкой компрессор обеспечивает достижение аммиачного хладагента необходимого давления и температуры для поглощения тепла из воды и образования льда. Высококачественный компрессор обеспечивает эффективную и надежную работу системы в течение длительного времени.

Газожидкостный сепаратор обеспечивает поступление в испаритель только жидкого хладагента. Это помогает поддерживать плавный и эффективный цикл охлаждения. Удаляя газовую фазу из хладагента, сепаратор повышает производительность системы, обеспечивая более эффективное охлаждение и более быстрое производство льда.

В испарителе происходит процесс охлаждения. Обычно это вертикальная или горизонтальная трубчатая система, в которой вода охлаждается и замерзает в лед. Поскольку хладагент поглощает тепло из воды, вокруг трубок образуется лед, который позже собирается в виде цилиндрического трубчатого льда.

Резервуар для хранения аммиака используется для хранения хладагента, когда он не используется или когда его необходимо заправить в систему. Этот резервуар предназначен для безопасного и надежного хранения аммиака, гарантируя, что в холодильной системе всегда будет достаточно хладагента для эффективной работы.

Льдогенераторы с аммиачными трубками предназначены для производства высококачественных трубок со льдом, прозрачных, сухих и идеально подходящих для различного промышленного и коммерческого применения. Получаемый лед тверд, прост в обращении и медленно тает, что делает его идеальным для использования в консервировании морепродуктов, пищевой промышленности и системах охлаждения.

Аммиак является высокоэффективным хладагентом, что делает льдогенератор с аммиачной трубкой одной из самых энергоэффективных доступных систем производства льда. Низкое энергопотребление не только помогает снизить эксплуатационные расходы, но и сводит к минимуму воздействие процесса производства льда на окружающую среду.

По сравнению с другими хладагентами аммиак оказывает гораздо меньшее воздействие на окружающую среду. Он имеет нулевой потенциал разрушения озона (ODP) и значительно более низкий потенциал глобального потепления (GWP), что делает льдогенераторы с аммиачной трубкой более экологичным выбором для предприятий, которые стремятся сократить выбросы углекислого газа.

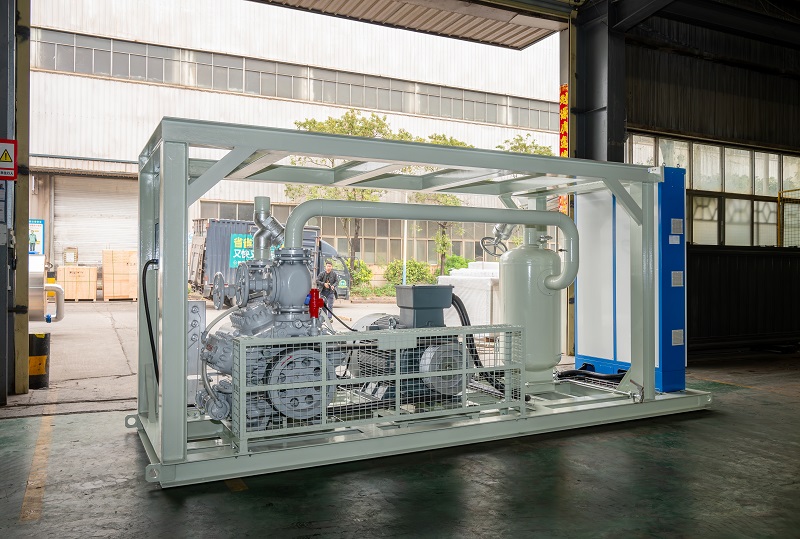

Льдогенераторы с аммиачными трубками доступны в различных размерах: от небольших до крупных машин промышленного масштаба. Ищете ли вы 5-тонный трубчатый льдогенератор или более крупный коммерческий трубчатый льдогенератор, вы можете найти подходящую модель, соответствующую вашим производственным потребностям. Модульная конструкция также позволяет предприятиям увеличивать производство льда по мере роста спроса.

Благодаря высококачественным компонентам, таким как двигатели Siemens и надежные компрессоры, льдогенераторы с аммиачной трубкой рассчитаны на длительный срок службы. Они спроектированы так, чтобы выдерживать суровые условия непрерывной эксплуатации и обеспечивать долгосрочную и надежную работу. Регулярное техническое обслуживание, включая отделение масла и контроль панелей управления, помогает обеспечить эффективную работу машины.

Хотите ли вы приобрести машину для изготовления трубчатого льда CBFI, изучить выставленные на продажу трубчатые льдогенераторы или инвестировать в крупномасштабную установку для производства трубчатого льда, это Важно учитывать размер, энергоэффективность и эксплуатационные характеристики машины. Среди множества доступных моделей и конфигураций вы можете найти идеальный промышленный трубчатый льдогенератор, отвечающий потребностям вашего бизнеса. Цены на машины для изготовления трубочек для льда варьируются в зависимости от мощности, характеристик и бренда, поэтому важно выбрать машину, которая предлагает наилучшее соотношение цены и качества.

Таким образом, льдогенераторы с аммиачной трубкой являются отличным выбором для предприятий, которым требуется высококачественное и энергоэффективное производство льда. Их расширенные функции, такие как двигатели Siemens, маслоотделители и мощные компрессоры, обеспечивают исключительную производительность и надежность. Если вам нужен коммерческий трубчатый льдогенератор для вашей фабрики по производству льда или трубчатый льдогенератор CBFI для вашей промышленной деятельности, аммиачная система предлагает идеальное решение для экологически чистого производства льда в больших объемах. производство.