Бренд:

CBFIПредмет номер.:

ABI100Порт доставки:

Guangzhou Portгарантия:

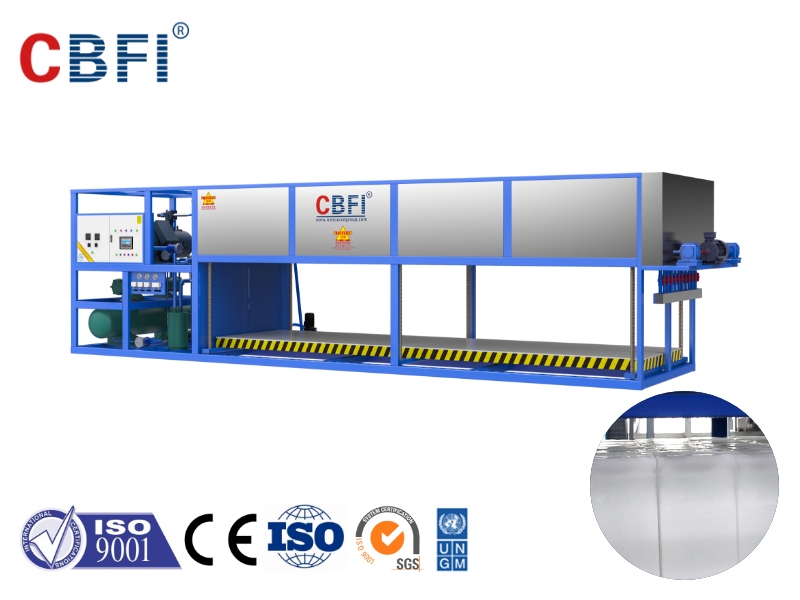

1 yearCBFI ABI100 10 тонн на 24ч блочный льдогенератор

CBFI преимущества автоматической льдогенератора

1. эффективный теплообмен, охрана окружающей среды и безопасность

2. автоматическое пополнение воды, автоматическое удаление льда

3. В ледяные блоки чистые и гигиеничные, соответствующие съедобным стандартам

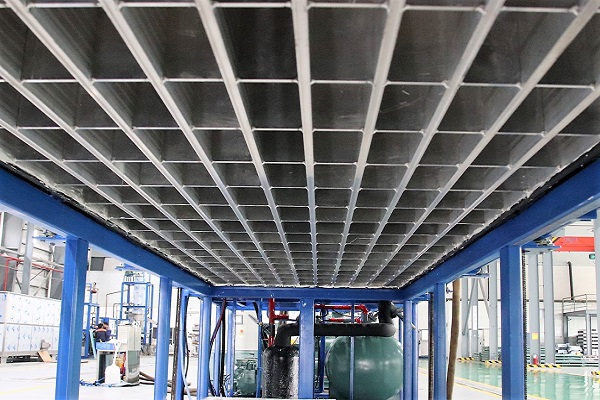

деталь машины

|  |  |

параметры

ABI100 параметры автоматических блоков льда название Ед. изм параметр Ханбелл параметр компрессора модель RC2-200B охлаждение Мощность (кВт) 98,3 Мощность (кВт) 39,1 температура конденсации Degr ee Цельсия (℃) 38 температура кипения градус Цельсия (℃) -15 температура окружающей среды градус Цельсия (℃) 28 температура воды градус Цельсия (℃) 16 хладагент R507 вольтаж V / P / HZ 380 / 3 / 50 подъемный двигатель Мощность (кВт) 4 градирни Мощность (кВт) 1,5 охлаждающий насос Мощность (кВт) 4 25кг глыба льда размер льда Д * Ш * В (мм) 315 * 120 * 760 размер машины Д * Ш * В (мм) 8100 * 2140 * 2300 30кг глыба льда размер льда Д * Ш * В (мм) 305 * 145 * 760 размер машины Д * Ш * В (мм) 10200 * 2200 * 2300 50кг глыба льда размер льда Д * Ш * В (мм) 435 * 150 * 850 размер машины Д * Ш * В (мм) 9000 * 2240 * 2500

изготовление блочного льда

|  |  |

|  |  |

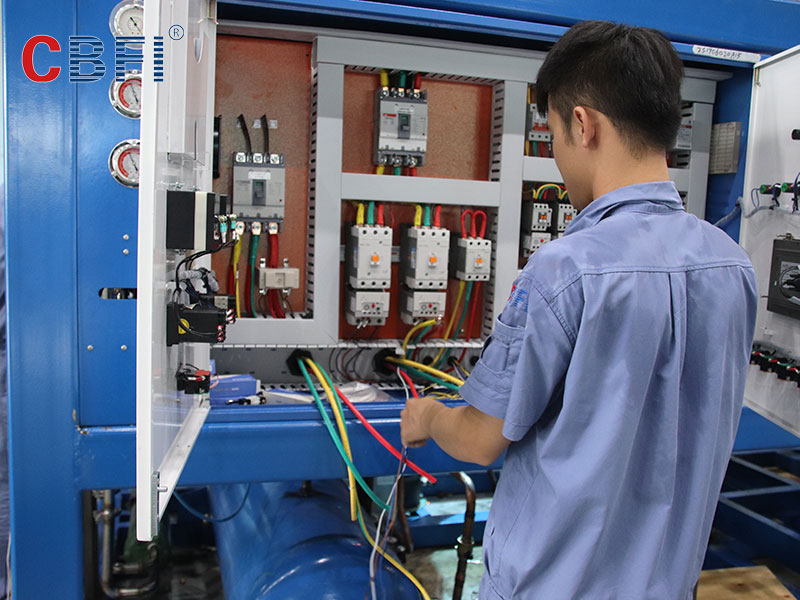

контроль качества

|  |  |

|  |  |